The Federal government in the early 1850s adopted The Bormann time fuse. This was used with spherical case-shot and common shell throughout the Civil War. Both Confederate and Federal sides experimented with Bormann fuses in rifled projectiles. The fuse was rarely used in longer ranged Parrott rifled case-shot projectiles because the fuse timing was too short (Pete George). By 1862, both sides used Bormann fuses in spherical projectiles only (Jones). The Confederates discontinued the use of the Bormann fuse altogether by early 1863 due to its poor field service.

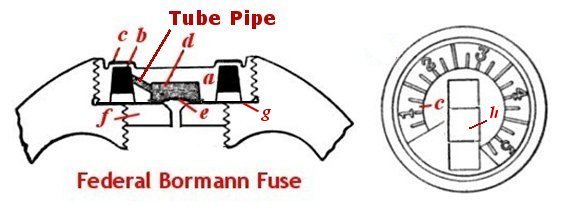

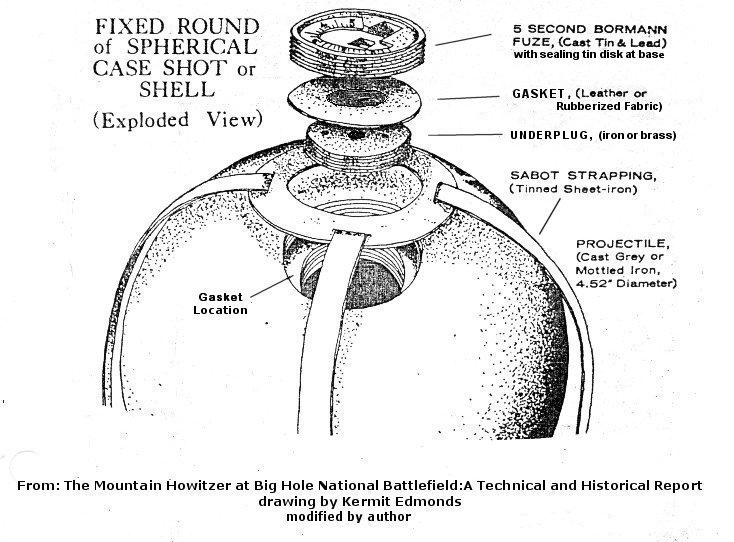

The Bormann fuse consisted of a threaded pewter or zinc disk, a (see illustration below) about 0.5 inches thick and about 1.6 inches in diameter that screwed into a corresponding hole in the projectile. The fuse disk overlies a brass or iron underplug, f, which separates the fuse from the projectile bursting charge. The underplug was screwed into a hole placed in the support shelf that is just above the main explosive charge of the projectile.

A curving U-shaped channel, b, was cast into the interior of the fuse and contained a trail of mealed powder that ended in a chamber, d, Just above the main bursting charge of the projectile. The fuse chamber charge is separated from the bursting charge by a thin tin disk, e, and, on detonation, the blast from the fuse charge passes through a central hole in the underplug, f, and ignites the projectile’s bursting charge.

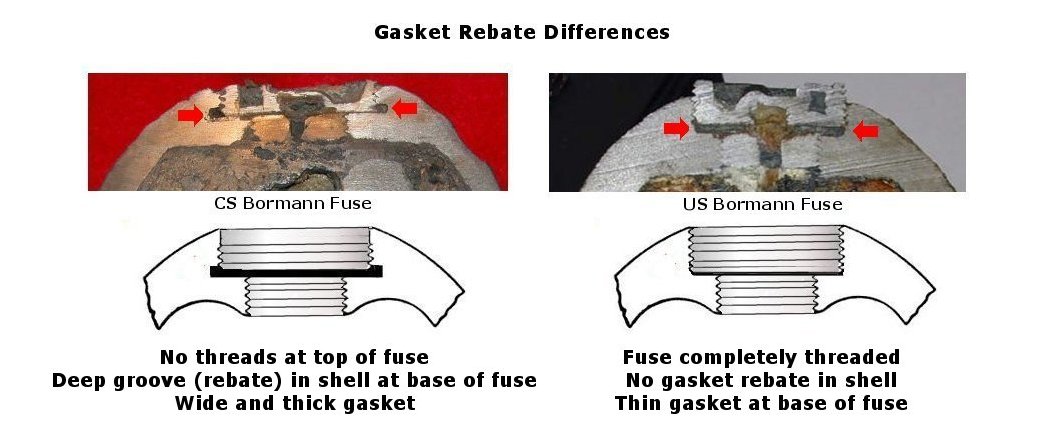

A thin head gasket of leather or rubber lies between the fuse and the underplug. The size of the recess for the head gasket is important to the identification of Confederate Bormann fuses from Federal (Pete George, personal comm.).

The tube pipe lies at the end of “b” curving U-shaped channel, that contained a trail of mealed powder that ended in a chamber, “d”, or “booster” charge lies just above the main bursting charge of the projectile. The fuse chamber charge is separated from the bursting charge by a thin tin-coated disk, “e”, and, on detonation, the blast from the fuse charge passes through a central hole in the underplug,”f”, and ignites the projectile’s bursting charge. Gasket at base of fuse is at “g”. The bridge protecting the tube pipe is located at “h”. The tube pipe was drilled not cast.

Above: the first picture shows the tube pipe and the “booster charge” cavity “d”. Normally this would contain rifle powder. The second picture shows the horseshoe retaining plug for the mealed timing powder. The third picture shows the thin perforated iron plug “e” that was coated with tin and pressed into the bottom of the “booster charge”. The plug was perforated before fuse installation in the field and prevented moisture from degrading booster charge powder.

On top of the Bormann fuse is a raised timing ring “c” that regulates when the bursting time in seconds of the projectile. On the timing ring, the whole seconds are shown in Roman numerals and the lines between the whole second lines represent times in ¼ seconds.

Timing marks on the Bormann fuse are shown as a series of lines of varying length, each represent a ¼ second of flight. The whole second lines are shown with Roman numerals. The longer lines represent ¼ second intervals between the whole seconds of flight.

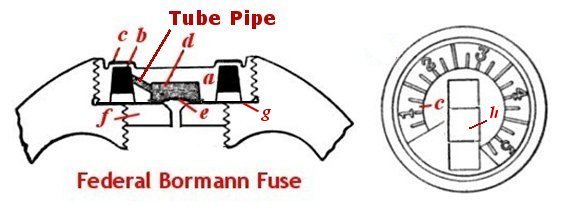

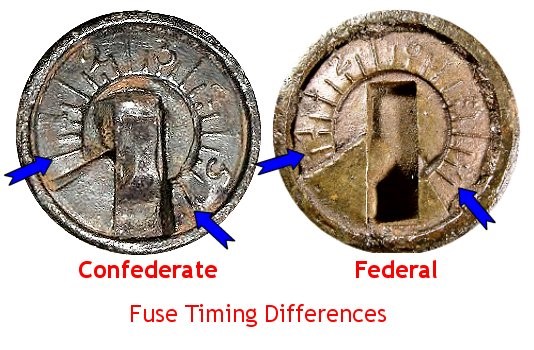

Dial Differences: Both Confederate and Federal timing dials had a total of 5.5 seconds. Timing dials of Confederate and Federal Bormann fuses was different. Confederate fuses ranged from ½ seconds to 5 ½ seconds. Federal fuses ranged from ¾ seconds to 5 ¼ seconds. See illustration below.

Timing dial face differences between the Federal and Confederate Borman fuses. The blue arrows show the differences. The Confederate fuse times from ½ to 5 ½ or 5 ¼ seconds and the Federal fuse times from ¾ to 5 ¼ seconds of flight. Large numbers on the left fuse was predominately by Confederates.

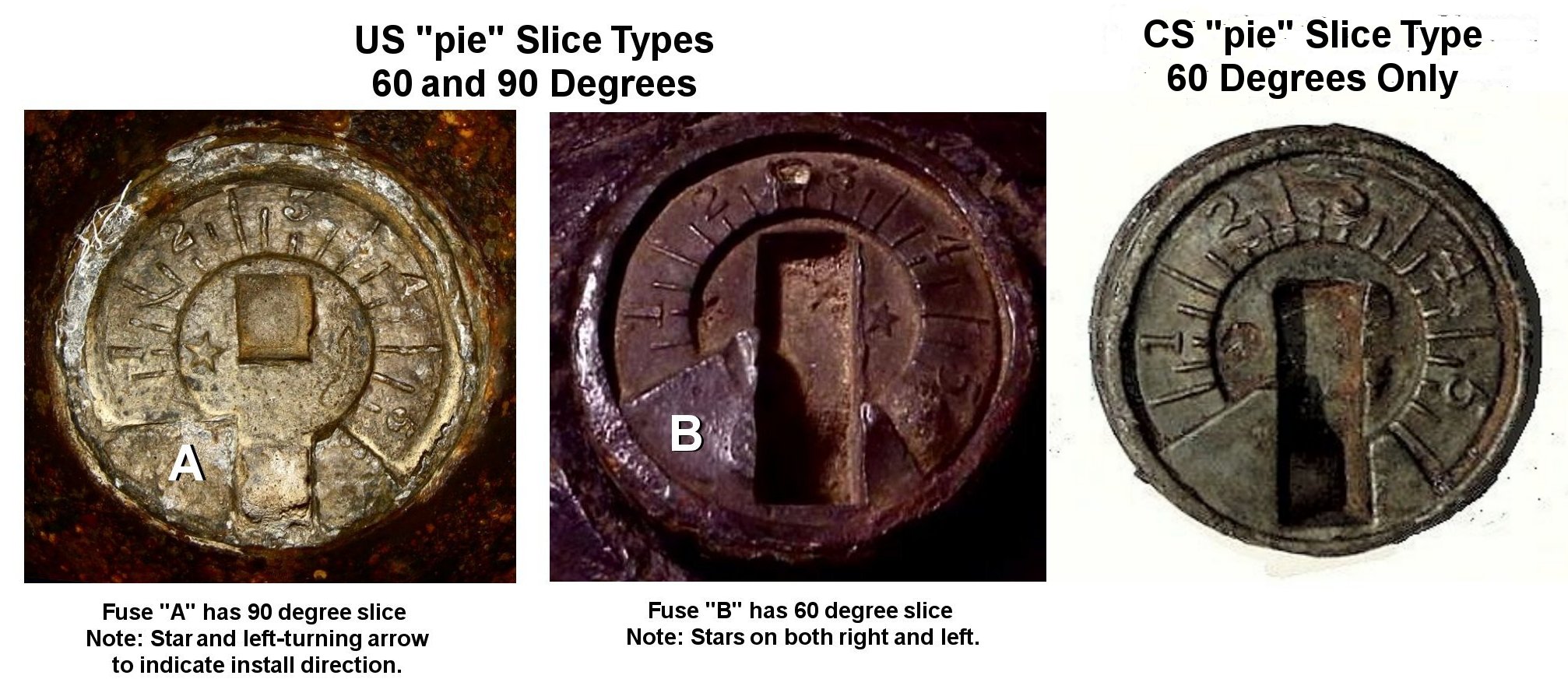

Pie Slices: The dials were also different in their “pie slice” located at the beginning of the timing dial face (near the 1 second timing line). Federal dials used a 60-degree slice and a 90-degree slice and Confederate dials used only the 60 degree slice (as shown below).

Tool Slots: Dial faces on the Bormann fuse are either double-slotted (two separate square holes as in fuse “A” above) or single slotted (as fuse “B” above).. Some believe that the double-slot was a later Federal innovation to prevent damage to the tube pipe hump covering the tube pipe. Double-slotted Borman fuses are strictly Federal. The Confederates never produced a double-slotted fuse. Single slotted Federal dials might be earlier.

Another telltale difference between Federal and Confederate Bormann fuses is the lack of threads at the top of the Confederate fuse as shown above. This may have contributed to the failure of the confederate fuses and their replacement with paper time fuses beginning in late 1862.

Marks and Arsenal Stamps: Marks and arsenal stamps on the dial face of the Bormann fuse can also be used for identification purposes. Several different stamps and marks have been identified and are shown in the table below. No marks or stamps exist of Confederate Bormann fuses.

|

Marks or Stamps on Bormann Fuse |

US |

CS |

|

Backwards “US” (pre-Civil War)* |

X |

|

|

Script “A”* |

X |

|

|

“Braille” numbers |

X |

|

|

Depressed star with counterclockwise arrow |

X |

|

|

Large Numbers |

x* |

X |

|

Raised “skeleton star” at bottom of key slot |

X |

|

|

Raised and depressed stars to side of key slot |

X |

|

* The various marks and stamps found on Bormann fuses appear to be arsenal identification stamps. The backward letters “US” pre-Civil War marking seem to be associated with the Springfield Armory and the Script “A” marking is known to be associated with the Allegheny arsenal. Raised and depressed stars might be associated, as with bullets, with the Washington arsenal. Large numbers on the dial faces appear to be used by both sides but seem to predominate in the Confederate side.

Caveat: It should be remembered that both sides tested each other’s projectiles. Captured projectiles could also have been used for artillery training or testing. Finding a Federal-marked Bormann fuse might not mean it was fired from Federal cannon.

There remains one other major difference between Confederate Bormann-fused spherical projectiles and those of the Federal: The nature of the groove (a.k.a. “rebate”) between the fuse and the underplug.

NOTE: The underplug may be made of brass or iron (as pictured above) in either Federal or Confederate. This is not a source identification criteria.

Artillery expert Peter George observed: “When war broke out, the Confederate Ordnance Department undertook to manufacture the Bormann time-fuse used by the Federals. The Confederates had terrible trouble with their version of the Bormann fuse.”

“The Confederates figured that the high incidence of premature explosions of their Bormann-fused shells was caused by the fuse "leaking" flame into the shell's bursting-charge cavity upon or just after firing. To prevent such flame-leakage, sometime in 1862 the CS Ordnance Dept. ordered a change in shape of the CS Bormann shells' fuse hole.”

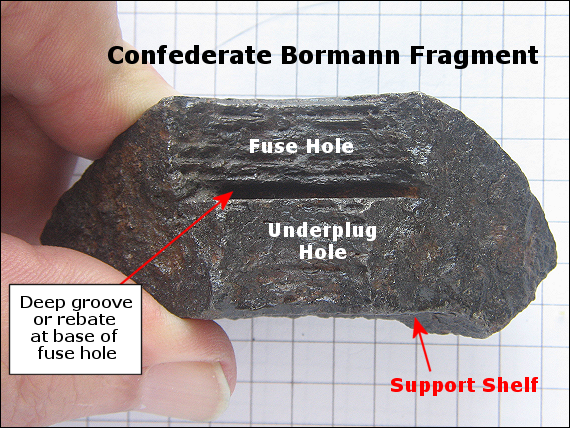

Confederate Bormann projectile fragments can be identified by the deep head gasket groove or rebate at the base of the fuse hole. This is not present in federal projectile fragments.

“It would henceforth be manufactured with a wide "rebate" (groove) at its bottom (below the fuse hole's screw-threads), in order to hold an extra-wide leather gasket (similar to a car-engine's head-gasket"), to help prevent flame from getting PREMATURELY into the shell's powder cavity and explode at the cannon's muzzle upon firing which is extremely bad for your own support-troops stationed in front of the battery.”

“To safeguard those troops, the CS Ordnance Department specified a modification in the shape of the CS Bormann fuse hole”.

“No Federal-made Bormann had the rebated area at the bottom of the main fuse hole's threads. So, generally, a Bormann shell that lacks the gasket-rebate is presumed to be Federally-made.”

“However, the Confederates did manufacture some Bormann shells prior to introducing the gasket-rebate (probably in late-1861). The fuse hole-fragments from them can be difficult to distinguish from US-made ones.”

The Confederates ultimately abandoned the Bormann fuse and replaced it with the paper time fuse.

Bormann Projectile Fragments: Relic fuse hole fragments from Bormann-fused spherical projectiles will always have a stair step appearance unless the support shelf is blown away during detonation.

Typically, a fuse hole fragment will contain a larger diameter set of threads associated with the fuse and a smaller diameter set of threads associated with the underplug located below the larger set. All Bormann-fused projectiles have this arrangement.

Projectile wall thickness will determine 12 Pdr spherical case-shot (with thin wall - 0.423 – 0.475 in.) from 12 Pdr common shell (with thick wall – 0.66 – 0.74 in.).- Ordnance Manual.

Projectile Identification from Shot Diameters: Case-Shot balls could be either lead or iron. However, lead was used more often than iron. Confederacy had a shortage of lead after 1862, so by mid-1863 all Confederate-made case-shot was made of iron. Federal case-shot was lead. Artillery Expert Peter George has passed on some valuable observations on the identification of case-shot projectiles from the diameter of their shot and other characteristics. These are shown in the table below.

|

Shot Diameter |

Metal |

Projectile |

Piece |

|

.55 to .72 |

Lead |

Bormann Spherical. Case-Shot |

6 – 12 – 24 Pdr. Smoothbore |

|

.54 + or - |

Lead |

Hotchkiss Case-Shot |

3 inch Ordnance Rifle |

|

.44 to .52 |

Lead |

3-inch Schenkl Case-Shot |

3 inch Ordnance Rifle |

|

.44 to .58 |

Lead |

CS Read Case-Shot |

3 inch Rifle |

|

.57 to .68 |

Lead |

US Parrott Case-Shot |

20 Pdr cal. Parrott Rifle |

|

.65 Musket Balls |

Lead |

Canister |

12 Pdr. Mountain Howitzer |

|

.65 |

Lead |

Dyer Case-Shot |

3 inch Ordnance Rifle |

|

.65 |

Lead |

Dyer Case Shot |

4.5 inch Siege Rifle |

Pete also observes that the number of shot balls contained in Civil War projectiles was variable and that small ordnance contractors were known to have cheated the government and did not fill their cases completely.

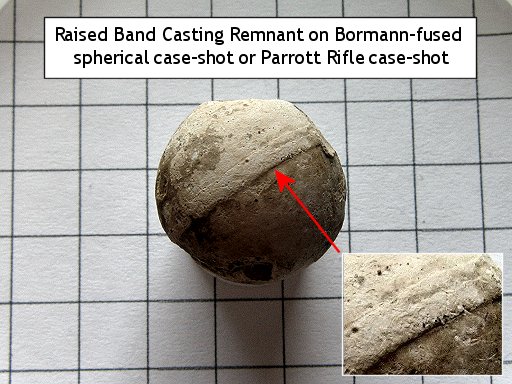

One other characteristic of the shot balls: If the shot contains a remnant raised casting band (as shown below) then it is from a Bormann spherical case-shot or a Parrott Rifle case-shot

Variation in the diameter of lead shot in any projectile type appears to be due to differences in contractor manufacturing. Only the weight of the projectile had to match the strict guidelines found in the Ordnance Tables. Uniformity of diameters in shot was often the result of manufacturing by the original projectile manufacturer or because of strict adherence to the parameters of the Ordnance Table.

Casting Characteristic: lead case-shot from Parrott Rifle or Bormann-fused projectiles often have a raised band which leads to projectile identification.

|

Fuse and Underplug Dimensions |

|||

|

|

Diameter |

Height |

Threads/inch |

|

Bormann Fuse |

1.6 |

0.5 |

12 |

|

Underplug |

1.0 – 1.08 |

0.32 – 0.65 |

12 |

Irwin US Thread Screw Pitch Gage (12018) at Ace Hardware

Author Poche’s Note: Almost the entire above article is based upon discussions with Civil War artillery expert Peter George and author Poche is indebted to him for his tireless efforts to train the author in this subject. Without his knowledge, this article could not have been written.

Good Additional Readings:

Dean S. Thomas, “Cannons: An Introduction to Civil War Artillery”; 1985; (ISBN 9780939631032); 72 pp.

United States Army Ordnance Depot, “The Ordnance Manual for the Use of Officers of the United States Army”; 1862 & reprinted 2006; University of Michigan Library Reprint; (ISBN 9781425559717); 540 pp. Also available through Google Books.

Dickey, Thomas S. & George, Peter C., “Field Artillery Projectiles of the American Civil War”; 1993; Arsenal Publications II; (ISBN 0960902201); 552 pp.

US War Department, “Instruction for Heavy Artillery”; 1851, 270 pp. Also available through Google Books.

US War Department, W.H. French; W. F. Berry and H.J. Hunt “Instruction for Field Artillery”; 1863, 281 pp. Also available through Google Books.

John Gibbon, “The Artillerist’s Manual”; 1860; (ISBN 1402114230); 568 pp. Also available through Google Books