The mid-west has a treasure trove of Civil War artillery carefully preserved in front of its public buildings and manicured civil war cemeteries. These treasures can sometimes be given names that are strange to the average on-looker of Civil War layperson

So, what gives with the title to this article? Craig Swain in his blog "To the Sound of the Guns" refers to models of siege mortars as "Iron-Frogs" because of their shape and size with respect to their larger brothers in field artillery. The frogs were 8- and 10-inch calibers and were designed to hurl a cast iron hollow shell filled with powder and paper fuse. The shells were intended to fall almost vertically onto fortifications or troops in high earthen trenches. On landing, they had a very destructive effect or if exploding in midair they dropped large deadly fragments on troops. They also had a psychological effect when fired on troops or civilians. General Abbott, in his book on uses of siege artillery, wrote the following on these effects by bombardment by siege artillery on the enemy:

| "On one occasion which came under my personal observation, a Confederate soldier was blown entirely over his parapet by the explosion of one of our shells; and his body lay, the clothing consumed by fire beyond the reach of his friends, who were deterred from approaching by our sharpshooters. To thus deprive an opponent of the accustomed protection of the trenches is well calculated to shake his nerves preparatory to an assault, or retard or prevent the pushing of siege approaches." |

Siege mortars were also used in the Revolutionary War and the Mexican War. In the Civil War, they began with the first shots against Fort Sumter. They were utilized in the sieges of Vicksburg, Petersburg, Richmond and against Mississippi River forts and and forts along the east coast. They probably reached their zenith during the sieges of Petersburg and Richmond near the end of the war.

Siege mortars were carried into position by siege wagons and moved short distances with sling carts. A larger and heavier class of mortars were sea coast mortars like the famous 13-inch "Dictator." These were originally intended for coastal protection against invading ships but they became intermixed in siege operations during the Civil War. They were so heavy and cumbersome to move that they required a specially built railroad car or ship to move them. These larger and heavier mortars were used at Yorktown and against Petersburg and Richmond.

Sling Cart moving a Model 1861 8-inch Siege Mortar

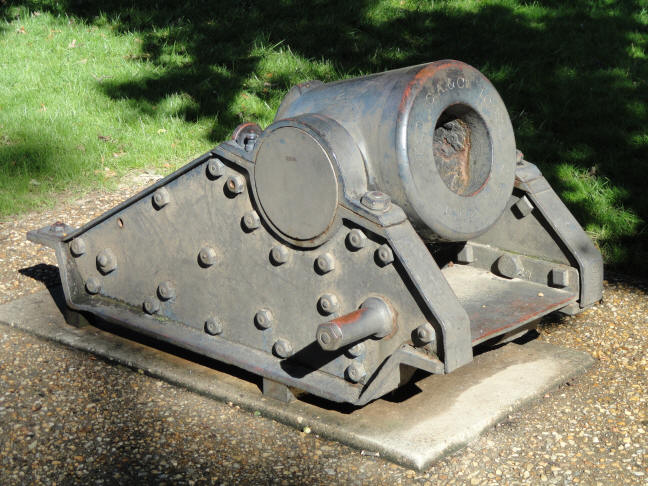

The place we are referring to by the title of this article is located in Danville, Illinois at its beautifully laid out Civil War cemetery called Soldier's Circle. Here the graves of the fallen are laid out in a circular configuration around a central statue much like Gettysburg cemetery. Next to the circular lines of graves are four 10-inch siege mortars of Model 1861 aligned to the points of the compass.

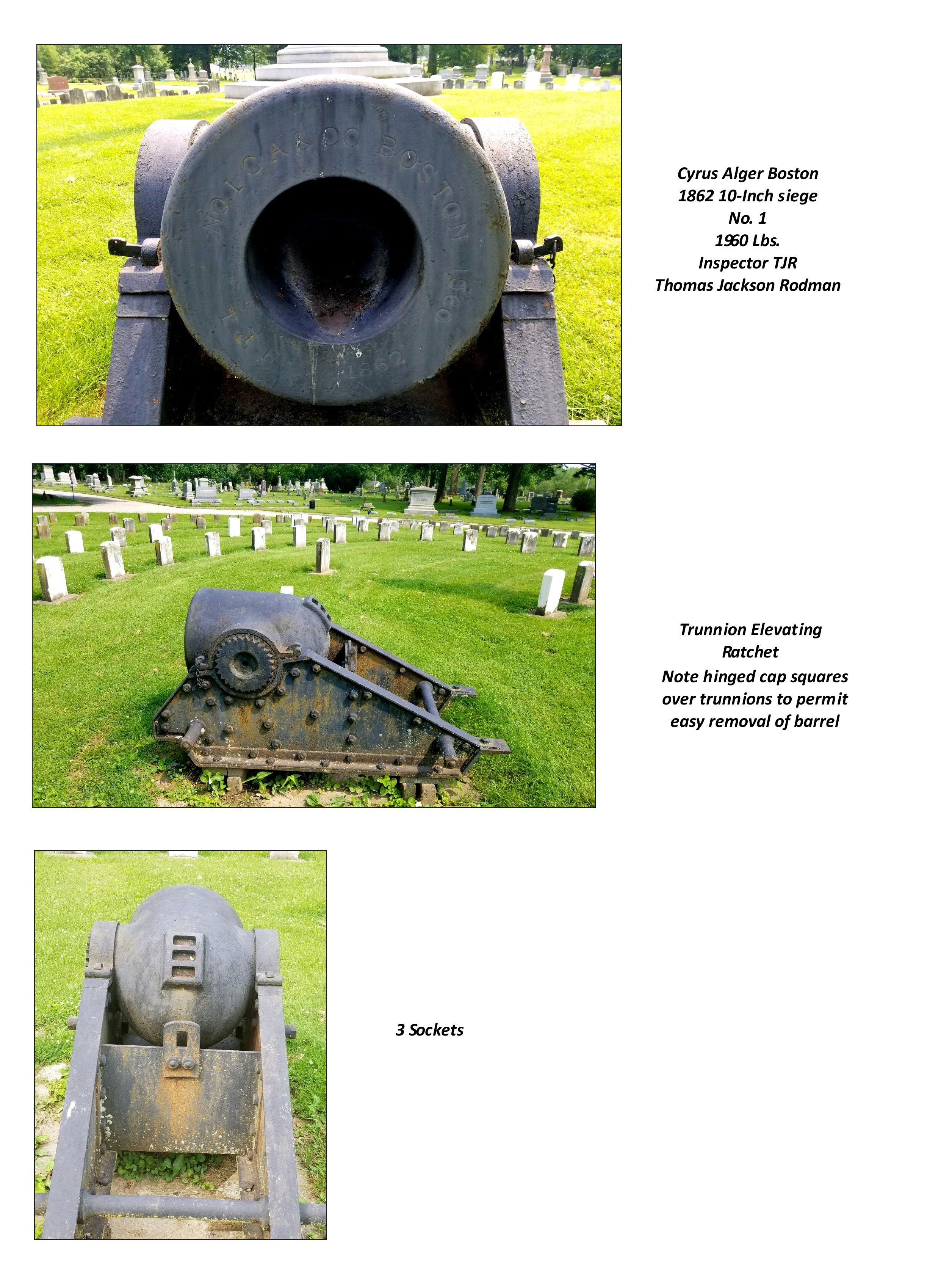

This location is one of the few places in the US where mortars of every foundry (Cyrus Alger of Boston, Fort Pitt of Pittsburg, and Scott Foundry of Seyfert, McManus of Reading) can be found together. All of the siege mortars at Soldier's Circle are Model 1861. At first view, they all appear to have an identical carriage but a closer inspection will show differences between the manufacturers.

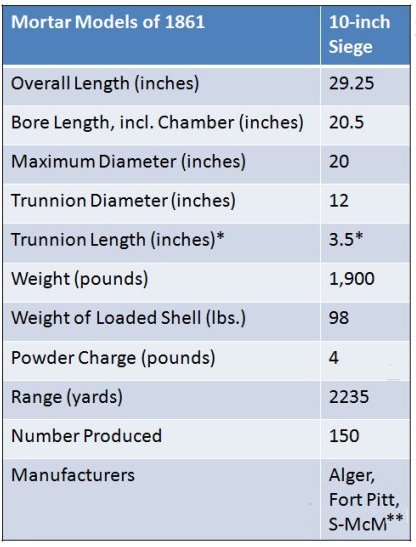

*There is a discrepancy seen between the length of trunnions

specified in the Ordnance Manual and those on surviving examples. Surviving 8-

and 10-inch mortars have 3.25 inch lengths.

** Scott Foundry of Seyfert, McManus & Company.

Siege mortars manufactured prior to the Model 1861 were a "hodge podge" of design, particularly in their carriages. The Model 1861 carriage and barrel were standardized.. The most obvious model difference is the large trunnion of the Model 1861 when compared to the 1841 Model.. Differences between the Model 1861 8-inch and 10-inch are shown below. The carriage difference allows for identification from old photographs and in person where distance is limited.

MODSM.jpg)

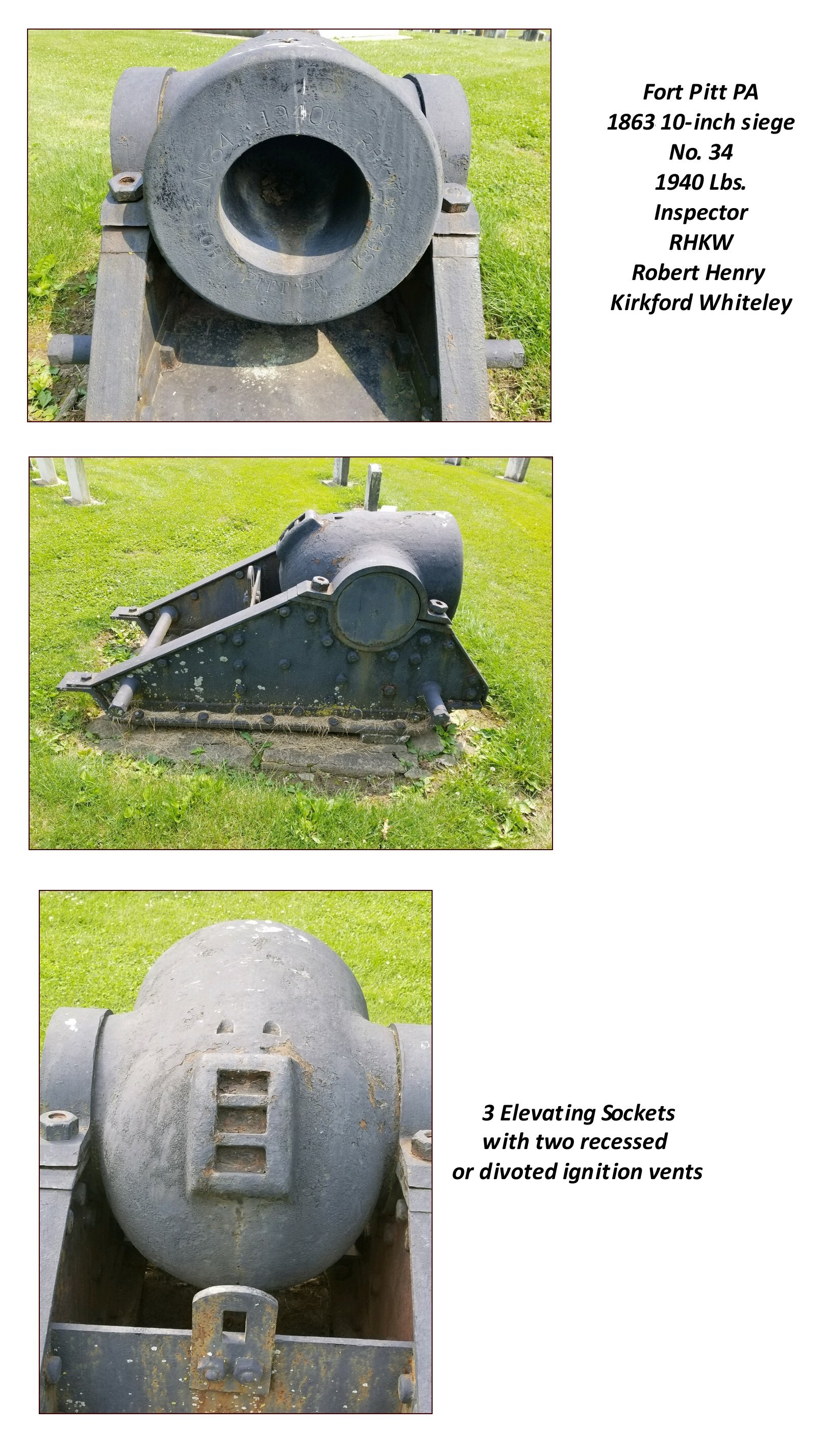

The Illinois mortars at the Soldier's Circle are all constructed to the same government specifications. There are differences by manufacturer. .All do not have lifting ear on the their barrels just above the trunnion. All have 4 maneuvering bolts sticking out of the cheeks of the carriage at its base. These were used for moving the mortar in place and for final aiming or pointing of the mortar to its target. All of the mortars have two ignition vents. One of the vents was completed to the ignition chamber and the other was not completed to the chamber It was to be used as a spare in case the main vent became unusable. Most of the vents are simple holes in the barrel but but one manufacturer (Fort Pitt Foundry) choose to recess the vents in their mortar.

Fort Pitt No. 34 cast in 1863 with recessed vents. Note "US' inspection stamp (blue star) and foundry barrel number "1620" (blue arrow) and possible removal scar? of lifting ear or "line of metal" pointing mark (blue arrow)

All of the Illinois mortars have rounded bore bottoms and the barrels was cast using a hollow-cast, water-cooled method that was suggested by Thomas J. Rodman. This allowed the mortar to use less powder and to shoot slightly farther that the Model 1841. .

|

|

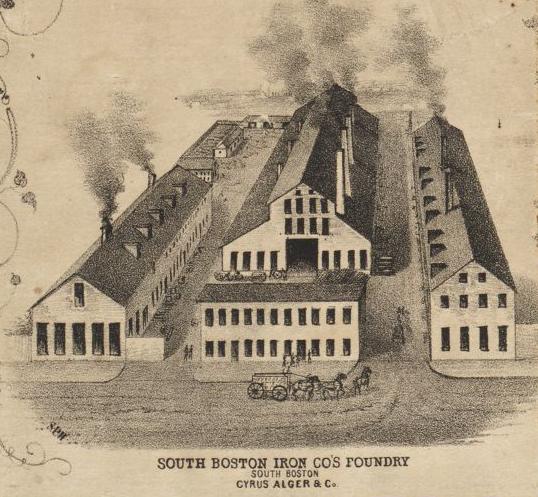

Cyrus Alger of Boston manufactured the next two Illinois mortars. Alger learned metal casting from his father. He set up a foundry near Boston and in 1809 he moved it to South Boston where it is rumored that he sold cannon balls to the Federal government during the War of 1812. By 1816, his foundry had grown into the South Boston Iron Foundry. He developed a process for purifying cast iron, producing a much stronger material. Alger also produced the first rifled gun in the nation.

Alger's Iron Foundry, South Boston, 1852

By 1860, the US Ordnance Board approved plans for a new Model 1861 mortar design, and all three mortar foundries began to produce the new 8-inch Model 1861. Alger was the first to cast the Model in April, 1862 and production continued to February, 1864. Ft. Pitt Foundry in Pittsburgh produced its first 8-inch mortar in January, 1863. Seyfert, McManus & Company, using the Scott Foundry in Reading, Pennsylvania, produced 50 examples starting in August 1864. All three foundries produced a total 170 8-inch Model 1861 mortars during the War.

Cyrus Alger, 1863 8-inch Siege Mortar, No. 20, 1028 Lbs.

Inspector Thomas Jackson Rodman

It is interesting to note that this mortar has no lifting ear like the Soldier's

Circle 10-inch mortars..

|

|

|

Alger delivered a second batch of 16 mortars from July 1863 to April 1864. This mortar would have been the 7th casting in the second batch and used the Rodman method of hollow casting This hollow casting method passed cooling water through the casting core of the barrel during casting. The controlled cooling of the metal of the barrel from the inside out, and allowed each successive layer to harden and compress the inner layers of the bore. The casting core would then be removed and the bore was polished in the final finishing. The process significantly reduced the casting cooling time and made the metal near the mortar bore stronger and gave a greater service life to the mortar. The two Alger casting batches brought the total mortar production to 26. |

|

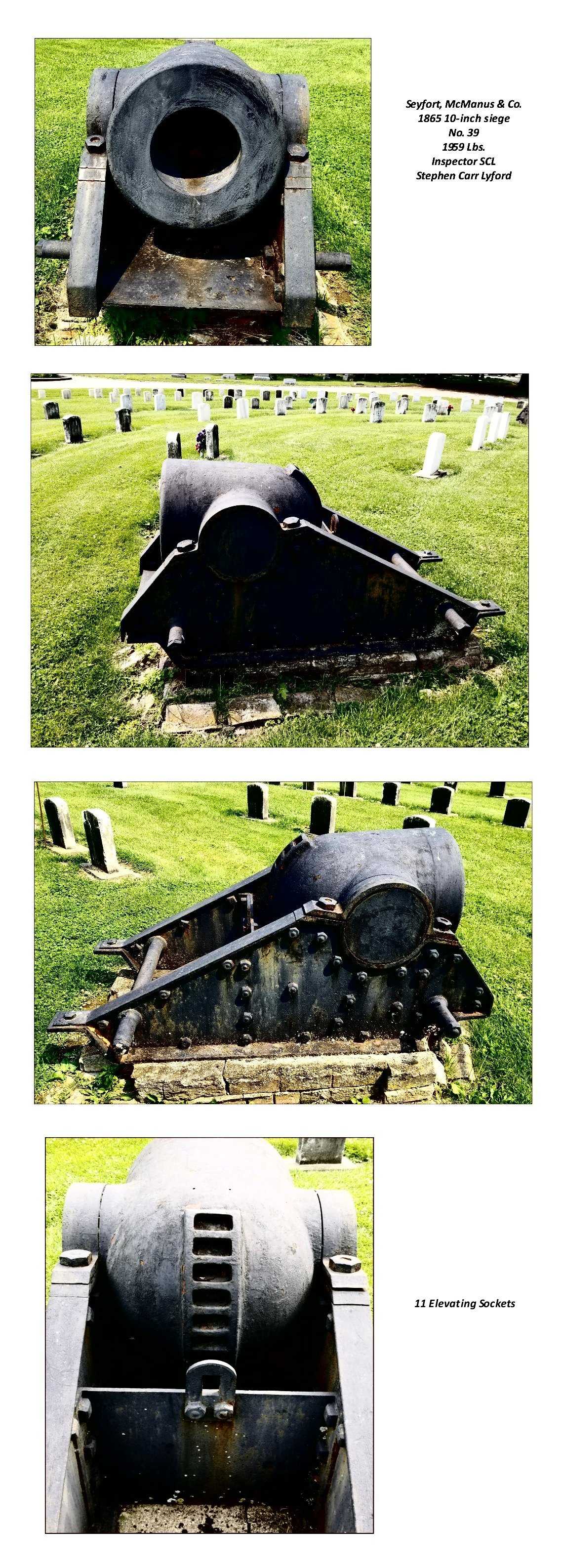

The foundry of Seyfort, McManus of Reading PA was built in 1854 and was reorganized as the Scott Foundry after General Scott and cast large naval guns and artillery during the Civil War

The foundry cast 50 10-inch siege mortars beginning in 1864. There are 21 known survivors of that production. |

How did mortars obtain the distance to their target?

Most of the time mortars were hidden from sight behind large wooden and earthen embankments Gunners were not able to see their target directly. Usually the firing angle was set to the maximum distance that could be obtained by the mortar (2235 yards for the Model 1861 10-inch siege mortar at 45 degrees or about 1.25 miles). if the target was less than that distance. the gunner had two options: vary the powder charge going into the barrel or adjust the shooting angle of the barrel to greater than 45 degrees with the elevating sockets. Often this was a trial and error process.

And so, There is a history of four very interesting mortars from a beautiful Civil War cemetery in Danville Illinois. There are not too many places where all of the mortar manufacturer's products can be seen side by side.

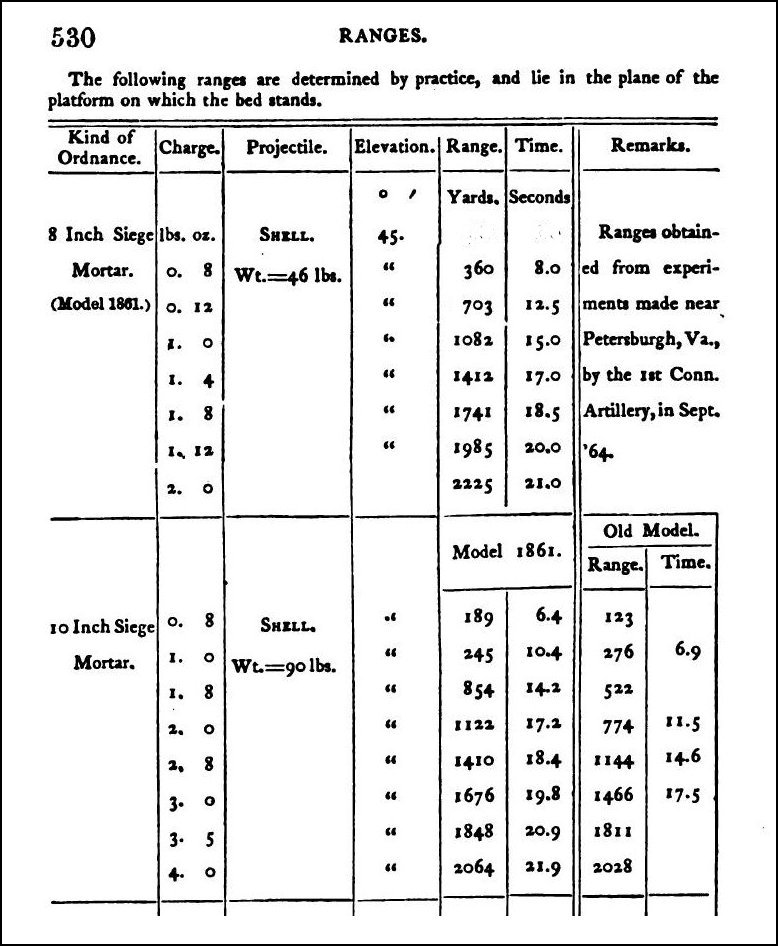

Ranges, Flight Times and Charges

|

Source: A Course of Instruction in Ordnance and Gunnery for Cadets US Military Academy 1867

Simple Equations to Estimate Flight Time and Charge from above chart

Model 1861 8-inch Siege Mortar

Flight Time = 0.0066(Range)+7.0568

Charge = 0.008(Range)+0.1789

Model 1861 10-inch Siege Mortar

Flight Time = 0.0017(Range)+7.3122

Charge = 0.0017(Range)+0.2543

Return to Previous Page